Spencer Dormer

Treading the unbeaten path can be tough, every geo or fieldie stamping through the bush or jungle knows that.

You also know to keep pursuing because you believe in your cause.

That's how the Recycled Discoverer Plastic Core Tray was born.

Mining on the Move into the Future

Earlier this year a mid-tier mining company's Exploration Manager and Geological Superintendent visited Dynamics G-Ex Perth office.

They had a mandate for the company to help take them into the future of mining.

They were clear; they didn't want to get left behind with outdated and old-school methods.

Essentially they weren't willing to be another 'Kodak' story.

Contentious Topic

With all break-through technologies you'll always get people saying 'it'll never happen'.

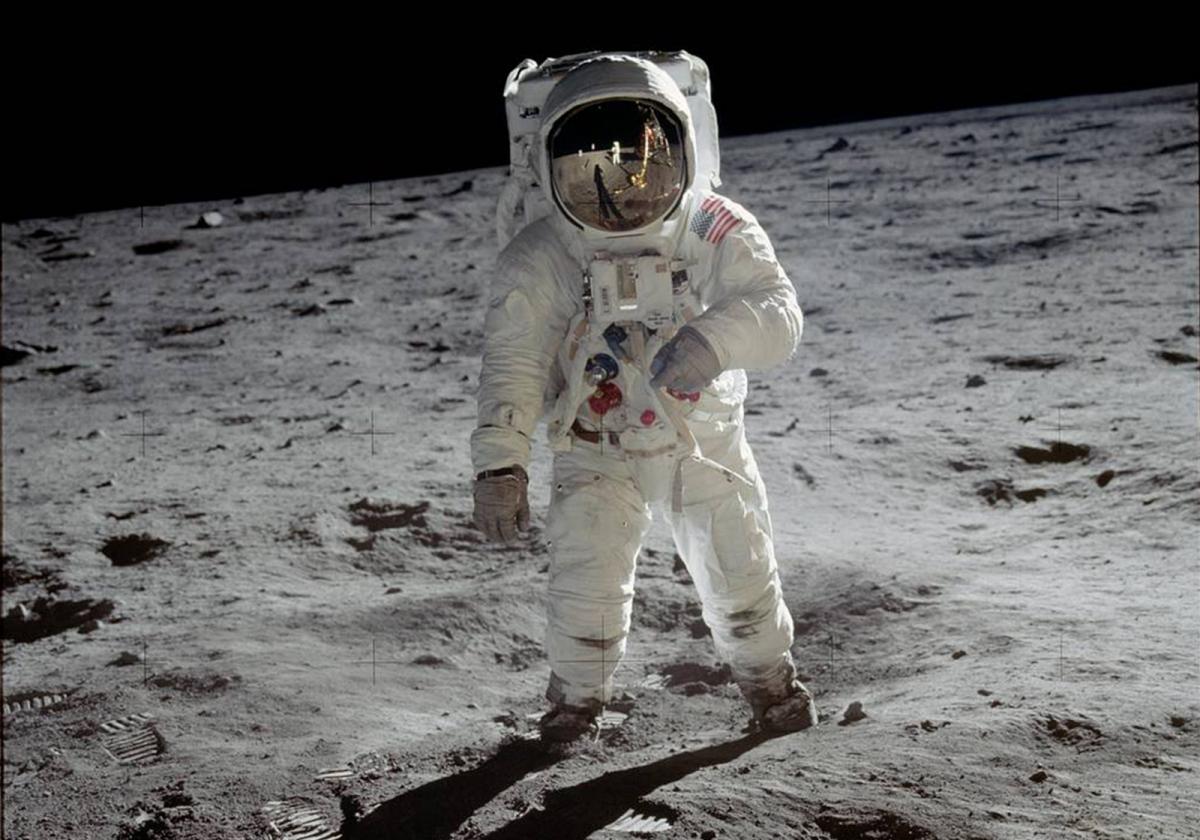

History has silenced those unwilling to step outside the comfort zone.

Mankind has walked on the moon, Edison was ridiculed by 'experts' about the light bulb, and the Wright brothers were right!

One of the biggest contentions of our day is the movement towards sustainable and eco-friendly solutions in our mining supply chains.

Discoverer actively pursued this concept with our Discoverer Core Tray manufacturing.

There's been interesting reactions from the competition.

But that's ok, because the company believes in pursuing the vision that is good for mankind, despite being the underdogs.

Dynamics wanted to openly discuss this so that you know what it means for you, and you are informed to make your own decision.

You may be wanting to stick with a virgin polymer, or you may be interested in looking at a sustainable, recycled option?

Either way, the choice is yours to make, regardless of this choice Dynamics believe in keeping you informed.

What is the mining industry demanding?

Pretty much this is where it starts and ends.

Is there a thirst to make a change?

In talking with Celia Hayes, Environmental Specialist at South32, she states:

"I would change the world by removing all single-use plastics from the supply chain and fast-track the wave around circular economy thinking by 20 years”.

That's a worthy goal from a futuristic thinker.

She's making revolutionary waves and the industry will have a lot to thank her for.

Virgin v Recycled Polymer

Westernex is one of the most well-known, respected and largest suppliers in the industry.

They have great team of people in Perth and also have strong beliefs in this area that recycled polymer core trays are a bad idea.

They made it public to you through their releases.

You can read the letter from John Wilder, Westernex Managing Director by clicking here.

Further to this was this post, outlining why Impala Core Trays are only made of virgin polymer and they'd never use recycled polymer.

Finally, they published this post, which talks about recycled plastic not being suitable for making core trays.

Whilst Dynamics G-Ex fully respects the decision of Westernex to stick with virgin polymer, as it is a longstanding tradition...

... the company wanted to go a little against the grain.

Environmental geologists, government agencies & major mining shareholders were asking us to do our bit in supporting their corporate social responsibility (CSR).

Dynamics realize that sticking with virgin may be the right choice for you and understand and sincerely respect that.

Here's what one longstanding customer had to say:

"There has been some speculation regarding the quality of the recycled core trays and their durability. We have had absolutely no issues to date."

- Kaye Raureti | Geology Supervisor | Red River Resources Limited

Is the Recycled Core Tray a viable option for me?

It could be, let's explore it.

You seem to us to be straight-shooters that don't beat around the bush.

You are getting our usual no-BS approach.

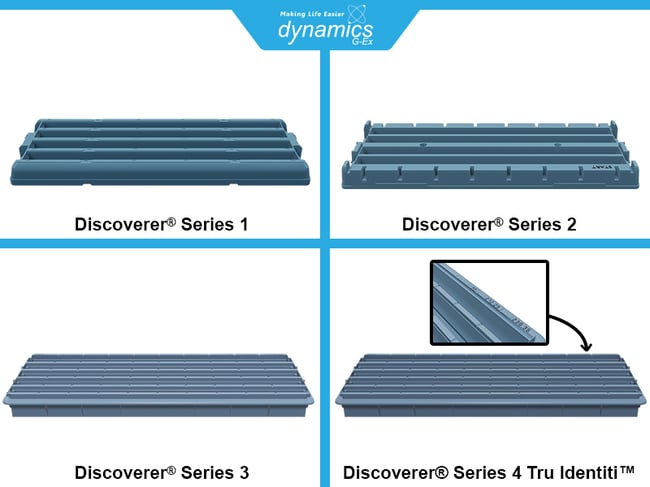

All Discoverer core trays have transitioned to an Air-Force Blue recycled polymer as of April 2020.

Miners & Explorers are finding using a Recycled Plastic Core Tray is a huge win for their ESG strategy, and probably one of the easiest changes to make a tangible impact.

However does a Recycled Plastic Core Tray last as long as a Virgin Plastic Core Tray?

When Discoverer® made the switch to manufacturing the Core Trays from repurposed Australian Kerbside Recycling, Dynamics needed assurance that this product would last just as long as a our original Virgin Plastic Tray that has been proven in the elements since 1993.

Following a robust QC Testing Process, by Australia's pre-eminent NATA & ISO Accredited Plastics Lab ExcelPlas, Discoverer® is the only Core Tray on the global market that has undergone this rigorous independent testing.

By using Discoverer®, you're looking after the Earth while drilling the Earth.

Absolute Peace of Mind Guaranteed.

Dynamics acknowledge the traditional recycled/regrind material is not suitable for some of the reasons outlined by Westernex.

Unfortunately what's been left out of the equation is the fact we are in a rapidly developing world where recycled material will be used in 70% of our plastic by 2025 (government stipulation).

Recycled polymer is better and more advanced than it's ever been... we are no longer in 2019.

🚀 to the future!

Watch the performance!

Little challenge: If you use Discoverer on site at the moment, try this little experiment and see

how you go.

This may debunk the 'very brittle' theory.

If things turn bad, act responsibly and stop. Otherwise have some fun!

Dynamics trust this helps you to choose, and the power of choice has been returned to you.

Have any more questions about Recycled Core Trays?

Leave them for us in the comments and we will answer them as soon as possible!