Travis Dormer

Most of us don’t really care to know the ins and outs of the plastics we use, like sample bags.

At a Glance

But we do however have a bigger responsibility to use the right plastics when drilling.

In this article I try to outline the differences in simple terms to give you confidence you're doing the right thing by our Resource Regulators, the EPA, etc.

Degradable Bags

Degradable bags are made from plastic with other chemicals added (including heavy metals) that cause the plastic to break down and disintegrate over time when exposed to sunlight and heat.

If degradable bags are left in the environment, they will break down into hundreds of tiny pieces of plastic.

It is obviously very difficult to remove hundreds of tiny pieces of plastic from the environment.

Biodegradable Bags

There is a mixed understanding, misuse, and poor definitions for the whole ‘biodegradable’ thing.

Often ‘biodegradable’ is used indiscriminately and because not everyone is clear on the term, it is easy to become unwittingly misled.

There are two main types of plastics marketed as biodegradable when they are likely not what you want:

Oxo-biodegradable (OBP)

Hydro-biodegradable (HBP)

Oxo-biodegradable plastic (OBP)

This plastic uses the same technology as conventional ‘normal’ plastic because it is made from fossil fuels (oil and natural gas).

The key difference is that it has an additive in the plastic to imitate bio-degradation.

Before the introduction of biodegradable materials, oxo-degradable was the ‘best’ option for an environmentally friendly solution.

This plastic breaks down to microplastics but does not break down at the molecular or polymer level like true biodegradable and compostable plastics.

The microplastics are left in the environment indefinitely until they eventually fully break down (which could take hundreds of years).

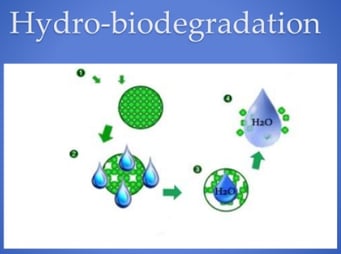

Hydro-biodegradable plastic (HBP)

Hydro-biodegradable plastic is made from plant sources such as corn, wheat, sugar-cane, petroleum-based sources or a blend of the two.

The degradation is initiated by hydrolysis (in simple terms, broken down by water).

These types of plastic degrade faster than oxo-biodegradable plastic; they are temperature resistant, and the only bioplastic that will decompose in both soil and water.

While both ‘sound’ good and are ‘biodegradable’, they are not environment-friendly.

These plastics break down to a size that you cannot see, and act like a cancer affecting the environment.

We've made a conscious effort not to supply any products made from the above-mentioned plastics as it conflicts with our honest approach in offering environment-friendly packaging.

The following article might help emphasise this point. https://www.theguardian.com/environment/2019/apr/29/biodegradable-plastic-bags-survive-three-years-in-soil-and-sea

There is little point in paying extra ‘green dollars’ for a ‘green product’ unless it gives you added benefit.

Ultimately we search for a solution that is environmentally responsible enough to bury.

The above options are not.

So what is eco-friendly?

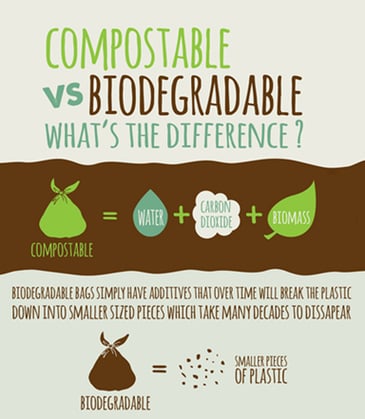

Compostable bags are considered as ‘biodegradable’ bags in Australia, but unlike the earlier examples they are made of natural plant starch, and do not contain any toxic material.

Compostable bags are broken down by micro organisms in the soil.

To be classified as compostable they must meet the Australian Standard for compostability AS 4736 and will have this compostable symbol and certification.

The below diagram may help explain this simply:

If you want to choose the option of burying your green UV sample bags rather than collecting them all after a drilling program, you can only do this legally and responsibly if you use a compostable bag.

To ensure this, look for the compostable logo!