Spencer Dormer

Inaccurate readings of your drill core orientation?

When it comes to drill core orientation, problems can arise from inexperience, lack of knowledge during the markup process and during the collection and interpretation of core samples.

The difference in techniques can also yield varying results.

Core orientation methods broadly fall into two categories: manual and digital. This will depend on the condition and competence of the rock's expected down hole, accuracy and reliability of the data and check back potential, ease of use, and of course, cost and schedule.

Manual methods include the spear, Ezy-Mark™ and Ballmark®, while digital methods include the Reflex and Coretell ORIshot, Devicore™ and Boart Longyear’s TruCore™ system.

The Manual Methods

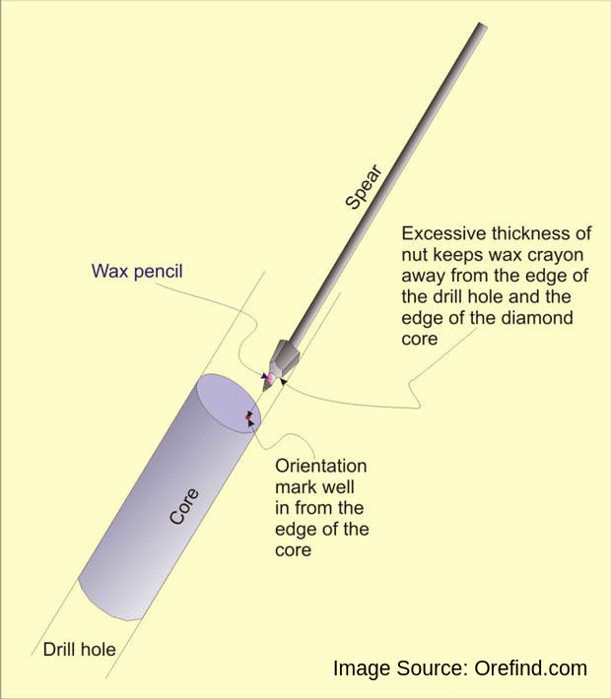

The spear method is the simplest and, for many years, has been relied upon to yield accurate and consistent data.

It involves use of a heavy steel spear with a sharp point or a wax-pencil tip on a wire line inside the drill rods once the inner tube has been removed.

Image source: Orefind.com

The spear will then hit the bottom of the hold, creating a mark on the next piece of rock. As the spear slides along the bottom of the rods, the mark or chip on the core will pinpoint its bottom edge. This is a straightforward core orientation process albeit it can be tricky.

Drillers must ensure that the tip—which should be a sharp taper—is firmly screwed into the spear so it will not bend. Otherwise, the results will be unreliable.

Lowering the spear should also be done carefully to create the desired single punch mark. If it is done too slowly, it will not make a mark. If done too fast, the spear might bounce and create multiple marks or streaked lines.

Determining the optimal speed is achieved through trial and error, based on the angle of the hole and the hardness of the rock.

With Ezy-Mark™, drillers and geologists must take into consideration factors such as a water table because this can prematurely fire before reaching the broken face on which the orientation mark needs to be made.

On the other hand, the Ballmark® system, which relies on an aluminum washer with a ball, also requires careful planning and expertise because if the washer is punched too soon, errors can occur.

The Digital Methods

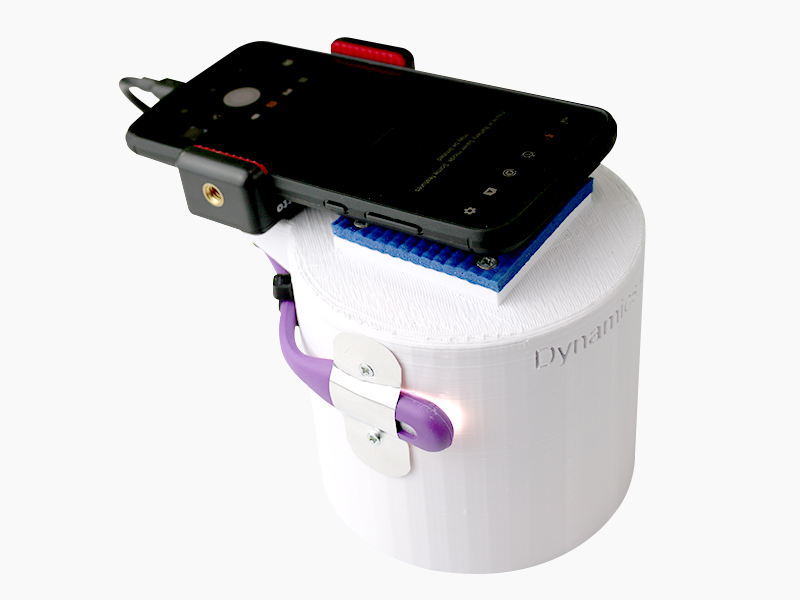

The digital methods, in most cases, deliver good orientation marks, providing usable orientation data for mine planning and resource definition, among others.

Among the digital methods, the Reflex can be considered as the most sophisticated when it comes to inner working, comprising digital read-outs and internal silicon accelerometers. It's ideal for vertical or angled holes as well as contact or non-contact core orientations.

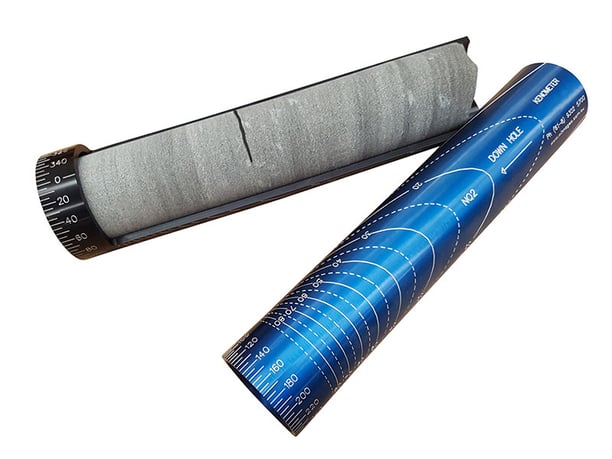

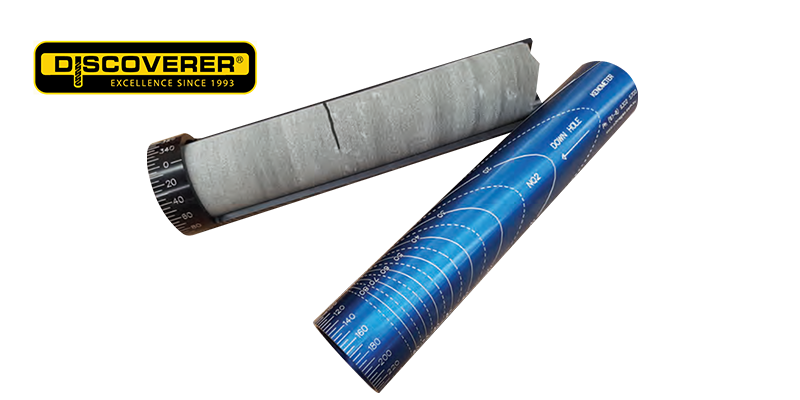

To measure the alpha-beta (α-β) of a planar feature, or gamma-delta (γ-δ) for a lineation, a Kenometer is most ideal.

A Kenometer is a user-friendly device which saves geologists' time in analysing core without compromising accuracy of readings.

It is a durable tool with permanent markings that ensures reliability, and its tough aluminum body makes it resistant to hazards on the field.

Watch the video below for a quick guide on how to use the Kenometer:

In any core orientation method, dialogue between the driller and the geologist is crucial.

It is important that the driller is comfortable with the chosen method and that the geologist understands the pros and cons so he or she can spot errors like bad orientation marks.

Drill core orientation is an evolving science but many of the problems can be averted by a well-prepared, well-coordinated and well-informed team with the right tools and equipment.

.png)